Weld Prep Services

Mastering Weld Prep with Houston Services Field Machining

Houston Services Field Machining (HSFM) has been an innovative force in the on-site field machining industry for over 30 years, offering unparalleled weld prep solutions that elevate your operations to new heights. We are dedicated to providing premium-quality, cost-effective services to a diverse range of clients from various sectors. By selecting HSFM as your weld prep partner, you’ll experience reduced downtime, increased productivity, and exceptional results. In this insightful guide, we’ll delve into the weld prep process, its advantages, applications, and why HSFM is the ultimate choice for all your on-site weld prep needs.

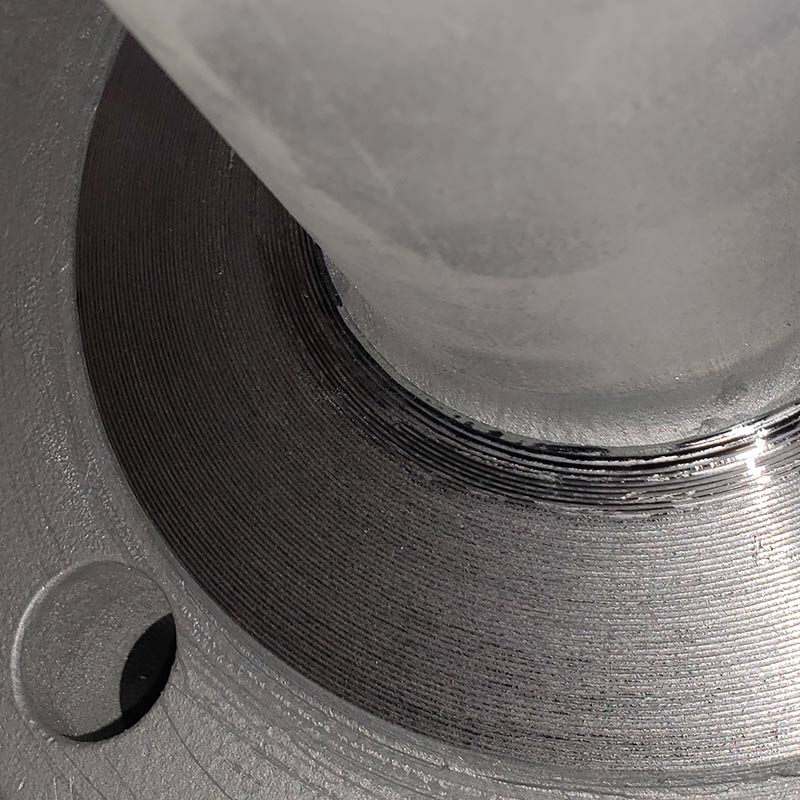

Unraveling the Weld Prep Process

Weld preparation, also known as weld prep, is the process of preparing the edges of metal components to be joined through welding. The process involves creating specific joint geometries, which are essential for producing strong, durable, and visually appealing welds. Depending on the materials, joint types, and welding techniques, weld prep can include processes such as grinding, cutting, beveling, or chamfering.

Advantages of Expert Weld Prep

Weld prep offers several key benefits to industrial operations:

Superior weld quality: Proper weld preparation ensures optimal joint geometry for various welding techniques, resulting in stronger, more durable, and visually appealing welds.

Increased efficiency: Accurate and precise weld prep reduces the need for time-consuming weld repairs, cutting downtime and boosting productivity.

Enhanced safety: Well-prepared weld joints reduce the risk of weld defects, ensuring the stability and reliability of the final product.

Versatility: Weld prep is essential for various joint types, materials, and welding techniques, making it ideal for diverse applications and industries.

Applications of Weld Prep

Weld prep is vital across a wide range of industries and applications, including:

Oil and gas: Preparing components for welding in pipelines, storage tanks, and processing equipment.

Power generation: Ensuring secure, reliable connections in steam, water, and gas pipes in power plants and other facilities.

Petrochemical: Fabricating high-quality welded joints for process piping systems, pressure vessels, and heat exchangers.

Shipbuilding: Creating strong, watertight welds for structural components, piping systems, and marine vessels.

Construction: Preparing steel structures for secure, load-bearing connections in buildings, bridges, and other infrastructure.

The HSFM Edge in Weld Prep

Houston Services Field Machining is home to a team of highly skilled professionals who possess the expertise and experience to provide best-in-class weld prep services. Our commitment to quality and cutting-edge equipment ensures that each weld joint meets your exact requirements and specifications.

With extensive experience, a focus on safety and quality, and competitive pricing, Houston Services is the premier choice for custom on-site machining solutions.

Houston Services Field Machining

Houston Services Field Machining is a reputable provider of top-quality on-site field machining and FCCU slide valve repair services, utilizing cutting-edge equipment and techniques to deliver efficient and cost-effective solutions.