Pipe Beveling Services

Enhancing Your On-Site Operations with Precision and Efficiency

For over three decades, Houston Services Field Machining (HSFM) has transformed the on-site field machining landscape by offering unparalleled pipe beveling solutions. Our mission is to provide exceptional value by delivering high-quality, cost-effective services that cater to clients from various industries. When you choose HSFM as your pipe beveling partner, you’ll experience reduced downtime, increased productivity, and outstanding results. In this all-inclusive guide, we’ll explore the pipe beveling process, its benefits, applications, and why HSFM is the ultimate choice for all your on-site pipe beveling requirements.

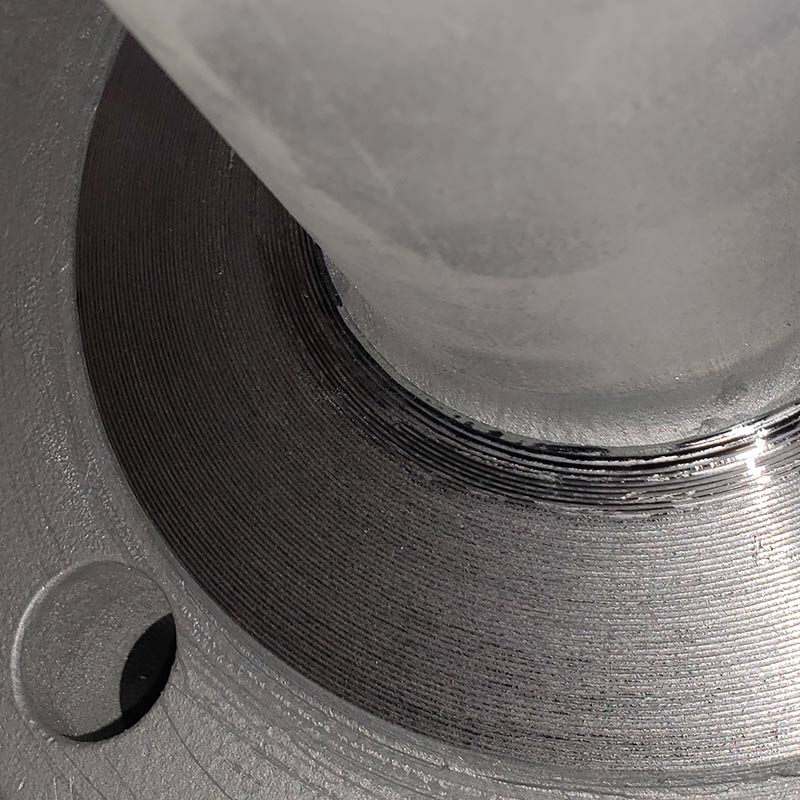

Pipe Beveling Demystified

Pipe beveling refers to the art of creating a specific angle or chamfer on the edge of a pipe or tube. This process readies the pipe ends for strong, leak-proof welds. Depending on the materials used, such as carbon steel, stainless steel, or alloys, pipe beveling can be executed using a variety of tools and techniques, including manual, hydraulic, or electric beveling machines.

The Power of Pipe Beveling

There are several reasons why pipe beveling is indispensable for industrial operations:

Unrivaled weld quality: Beveling forms the perfect joint geometry for full penetration welds, minimizing defects and ensuring robust, leak-proof connections.

Elevated efficiency: Precise bevels enable quicker, more effective welding, cutting downtime and boosting productivity.

Enhanced safety: Beveled pipe ends mitigate the risk of injury from sharp edges during handling and installation.

Adaptability: Pipe beveling is suitable for a diverse range of pipe sizes, materials, and wall thicknesses, making it ideal for various applications and industries.

Pipe Beveling in Action

Pipe beveling is crucial across multiple industries, with applications such as:

Oil and gas: Welding pipelines and other components during installation, maintenance, and repair procedures.

Power generation: Securing reliable connections for steam, water, and gas pipes in power plants and other facilities.

Petrochemical: Crafting high-quality welded joints for process piping systems and pressure vessels.

Shipbuilding: Producing strong, watertight welds for piping systems on ships and offshore structures.

Construction: Preparing steel structures for secure, load-bearing connections.

The HSFM Advantage in Pipe Beveling

Houston Services Field Machining’s seasoned team of professionals possesses the knowledge and expertise to provide best-in-class pipe beveling services. With our cutting-edge equipment and commitment to quality, we guarantee that each pipe bevel meets your exact requirements.

With extensive experience, a focus on safety and quality, and competitive pricing, Houston Services is the premier choice for custom on-site machining solutions.

Houston Services Field Machining

Houston Services Field Machining is a reputable provider of top-quality on-site field machining and FCCU slide valve repair services, utilizing cutting-edge equipment and techniques to deliver efficient and cost-effective solutions.