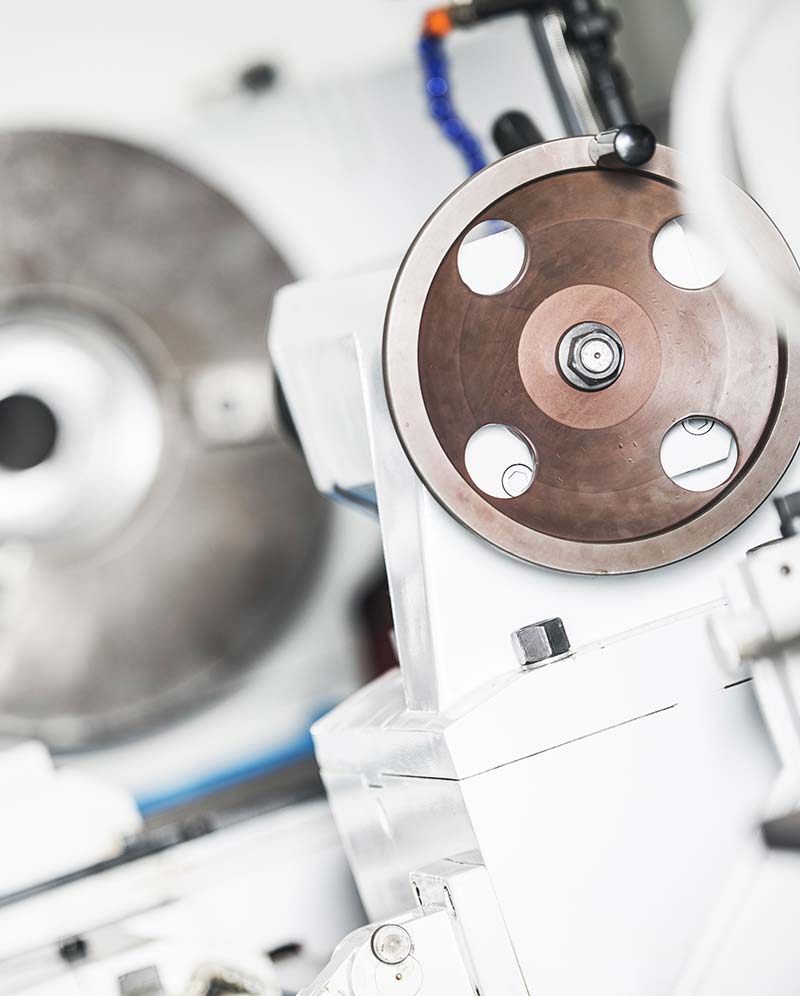

Line Boring Services

Elevate Your Operations with Houston Services Field Machining

For over three decades, Houston Services Field Machining (HSFM) has been a driving force in the on-site field machining world, offering top-notch line boring solutions that streamline your operations. Our unwavering commitment to delivering first-rate, cost-effective services has enabled us to serve a diverse range of clients across multiple industries. By choosing HSFM for your line boring needs, you’ll benefit from reduced downtime, increased productivity, and outstanding results. In this in-depth guide, we’ll examine the line boring process, its advantages, applications, and why HSFM is the premier choice for all your on-site line boring needs.

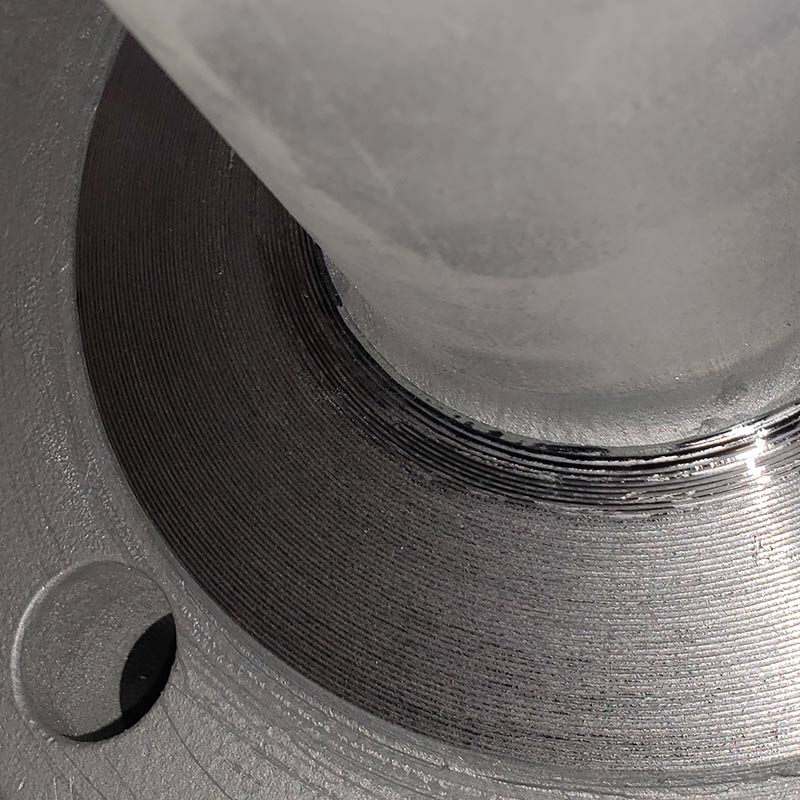

Decoding the Line Boring Process

Line boring is a specialized machining process used to restore damaged or misaligned bores or create new ones. This process involves using a rotating cutting tool to reestablish the original alignment or create new, precise, and straight holes. Line boring is commonly employed in various industries to repair or enhance equipment performance, reduce vibrations, and extend the service life of components.

Benefits of Skillful Line Boring

Line boring offers several significant advantages to industrial operations:

Enhanced equipment performance: Properly aligned bores ensure optimal performance, reduced vibrations, and improved efficiency of machinery and equipment.

Extended component life: Line boring restores components to their original specifications, increasing the service life of machinery and minimizing the need for costly replacements.

Reduced downtime: Efficient line boring processes minimize downtime and maximize productivity, ensuring your operations run smoothly.

Versatility: Line boring is suitable for a wide range of applications and industries, making it an indispensable process for maintaining and repairing equipment.

Line Boring in Action

Line boring is essential across various industries, with applications including:

Heavy equipment repair: Restoring alignment in bores of construction and mining equipment, such as excavators, bulldozers, and loaders.

Manufacturing: Ensuring precise alignment in machine tool components, such as bearings, bushings, and gearboxes.

Oil and gas: Repairing and maintaining drilling and production equipment, such as mud pumps and top drives.

Power generation: Maintaining and repairing turbines, generators, and other equipment in power plants and renewable energy facilities.

Marine and shipbuilding: Restoring alignment in engine blocks, stern tubes, and other critical components of ships and marine vessels.

The HSFM Advantage in Line Boring

Houston Services Field Machining boasts a team of seasoned professionals with the knowledge and expertise to provide top-tier line boring services. Our dedication to quality and state-of-the-art equipment ensures that each line boring project meets your exact requirements and specifications.

With extensive experience, a focus on safety and quality, and competitive pricing, Houston Services is the premier choice for custom on-site machining solutions.

Houston Services Field Machining

Houston Services Field Machining is a reputable provider of top-quality on-site field machining and FCCU slide valve repair services, utilizing cutting-edge equipment and techniques to deliver efficient and cost-effective solutions.