Flange Refacing

Flange refacing is a crucial process in the world of industrial manufacturing and maintenance. It involves the machining of the sealing faces of flanges, ensuring that they are perfectly flat and parallel. Flange refacing is an essential step in the maintenance of pipelines, valves, and other industrial equipment, as it helps to prevent leaks and other costly downtime events.

30 Years

At Houston Services Field Maching, we have over 30 years of experience providing high-quality flange refacing services to our clients. Our team of expert technicians is trained in the latest techniques and technologies, ensuring that we deliver the best possible results to our customers.

Why Flange Refacing Is Important

Flange refacing is an important process in the maintenance of industrial equipment for several reasons. First and foremost, it helps to ensure that flanges are perfectly flat and parallel, which is critical for creating a proper seal. Flange misalignment or damage can result in leaks, which can be costly to repair and cause significant downtime.

Another important reason to consider flange refacing is to extend the lifespan of your equipment. Flange damage can cause premature wear and tear on other components, leading to more frequent maintenance and repair needs. By ensuring that flanges are properly maintained through regular refacing, you can help to extend the lifespan of your equipment and save money in the long run.

Flange Refacing Process

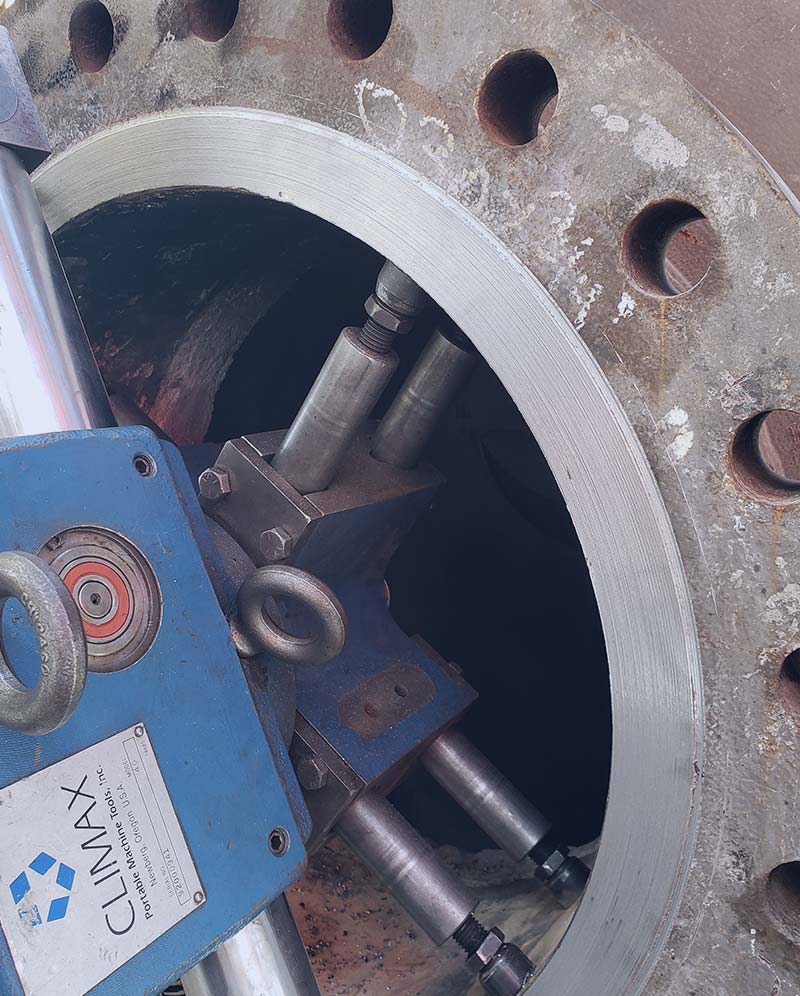

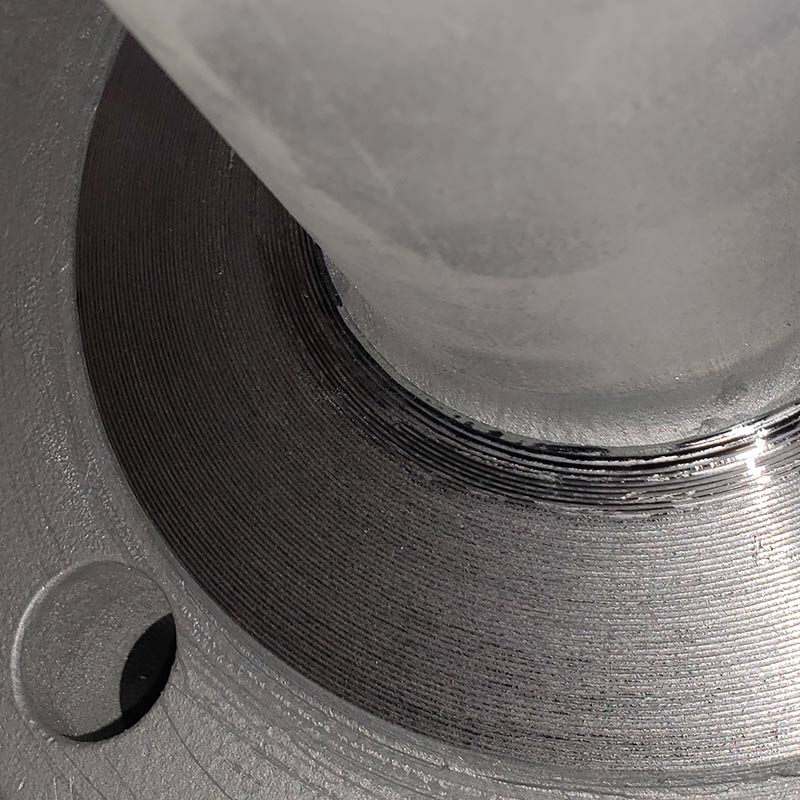

At Houston Services Field Maching, we use the latest techniques and technologies to deliver high-quality flange refacing services. Our process involves several steps to ensure that flanges are perfectly flat and parallel, including:

Inspection: Our technicians will inspect the flanges to determine the extent of any damage or misalignment.

Preparation: The flange surfaces are cleaned and prepared for machining.

Machining: Our team will use specialized tools and machinery to machine the flange surfaces to the required specifications.

Quality Control: The flange surfaces are inspected and measured to ensure that they meet the required specifications.

Reporting: A detailed report is provided to the customer outlining the work performed and the results achieved.

Our flange refacing process is designed to be efficient and cost-effective, ensuring that our customers can get back to full productivity as quickly as possible.

Benefits of Flange Refacing with Houston Services Field Maching

There are several key benefits to choosing Houston Services Field Maching for your flange refacing needs, including:

Experience: We have over 30 years of experience providing high-quality field machining services to industrial clients across various sectors.

Expertise: Our team of technicians is highly trained and experienced in the latest techniques and technologies, ensuring that we deliver the best possible results to our customers.

Quality: We are committed to delivering high-quality work and ensuring that our customers are completely satisfied with the results.

Cost-Effective: Our flange refacing services are designed to be cost-effective, helping our customers to save money in the long run.

Efficiency: We understand the importance of minimizing downtime and maximizing productivity, which is why we work quickly and efficiently to complete our work.

Choose Houston Services Field Machining for Your Flange Refacing Needs

If you’re in need of flange refacing services, look no further than Houston Services Field Maching. Our team of expert technicians is standing by to deliver high-quality and cost-effective solutions to help you minimize downtime and maximize productivity. Contact us today to learn more about our services and how we can help you with your flange refacing needs.

With extensive experience, a focus on safety and quality, and competitive pricing, Houston Services is the premier choice for custom on-site machining solutions.

Houston Services Field Machining

Houston Services Field Machining is a reputable provider of top-quality on-site field machining and FCCU slide valve repair services, utilizing cutting-edge equipment and techniques to deliver efficient and cost-effective solutions.