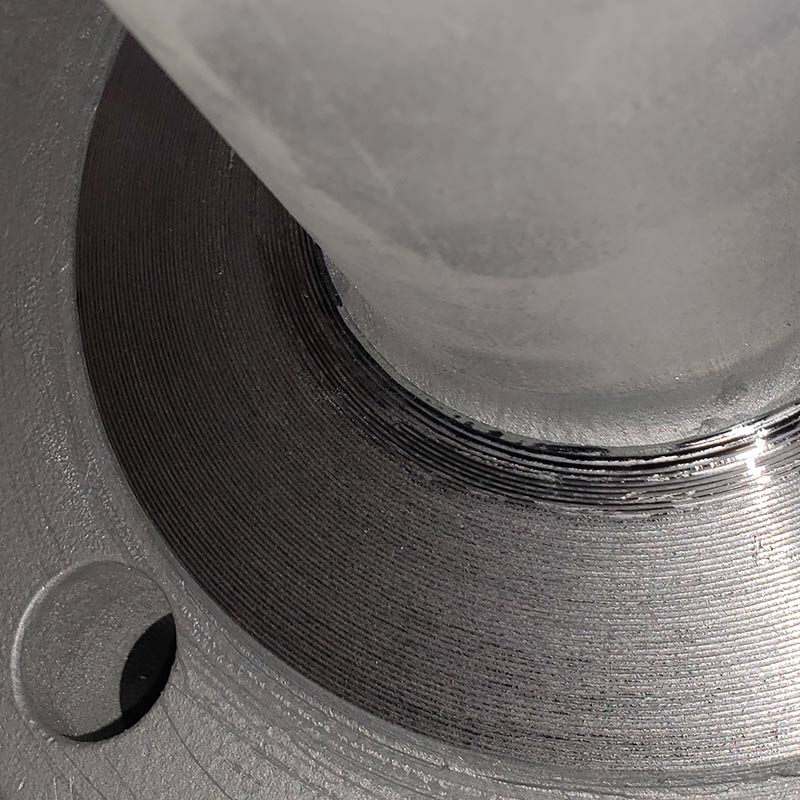

Custom Machining

Unleashing the Potential of Custom Machining with Houston Services Field Machining

Houston Services Field Machining (HSFM) has been at the forefront of the on-site field machining industry for over 30 years, delivering unparalleled custom machining solutions that revolutionize your operations. Our steadfast dedication to providing exceptional, cost-effective services has earned us the trust of clients from a variety of sectors. By partnering with HSFM for your custom machining needs, you’ll enjoy reduced downtime, increased productivity, and remarkable results. In this comprehensive guide, we’ll explore the custom machining process, its benefits, applications, and why HSFM is the ultimate choice for all your on-site custom machining requirements.

Unraveling the Custom Machining Process

Custom machining is the process of creating unique parts or components tailored to the specific needs of a project or application. This can include a wide range of techniques, such as milling, turning, grinding, and drilling, to produce precise, high-quality components that meet exact specifications. Custom machining offers the flexibility to cater to unique design requirements, material constraints, and production volumes, ensuring the ideal solution for each individual project.

Advantages of Expert Custom Machining

Custom machining offers several key benefits to industrial operations:

Precision and quality: Custom machining ensures that each component is manufactured to the highest standards, guaranteeing optimal performance and durability.

Flexibility: Custom machining accommodates a wide range of materials, designs, and production volumes, making it suitable for various applications and industries.

Streamlined production: Custom machined components can reduce assembly time, minimize the need for adjustments, and increase overall productivity.

Cost-efficiency: Custom machining allows for the efficient use of materials, reducing waste and lowering production costs.

Applications of Custom Machining

Custom machining is vital across a broad spectrum of industries and applications, including:

Aerospace: Producing intricate components for aircraft engines, landing gear, and avionics systems.

Automotive: Manufacturing custom parts for engines, transmissions, and suspension systems.

Medical: Creating specialized instruments, implants, and diagnostic equipment.

Oil and gas: Producing bespoke components for drilling, production, and processing equipment.

Renewable energy: Developing custom parts for wind turbines, solar panels, and other clean energy technologies.

Top Reasons to Partner with HSFM for Your Custom Machining Needs

- Unparalleled expertise: With over 30 years of industry experience, our team is equipped to handle even the most complex custom machining projects with ease.

- Unmatched precision: Our advanced equipment and strict quality control measures guarantee that every custom machined component aligns with your specifications.

- Budget-conscious solutions: Our focus on efficiency and competitive pricing ensures the greatest return on your investment.

- Tailored service: We customize our custom machining services to cater to each client’s unique needs, delivering solutions that help you achieve your goals.

- Comprehensive support: From the initial consultation to project completion, our team is dedicated to providing outstanding customer service at every stage.

With extensive experience, a focus on safety and quality, and competitive pricing, Houston Services is the premier choice for custom on-site machining solutions.

Houston Services Field Machining

Houston Services Field Machining is a reputable provider of top-quality on-site field machining and FCCU slide valve repair services, utilizing cutting-edge equipment and techniques to deliver efficient and cost-effective solutions.