Counterboring Services

The Ultimate Solution for Your On-Site Machining Needs

Houston Services Field Machining (HSFM) has been an industry leader in providing top-of-the-line on-site field machining services, including exceptional counterboring solutions, for over 30 years. Our dedication to delivering high-quality and cost-effective solutions has enabled us to serve a diverse range of clients across various sectors. By partnering with us, you can minimize downtime and maximize productivity in your industrial operations. In this comprehensive guide, we’ll discuss the counterboring process, its benefits, applications, and why HSFM should be your go-to choice for all your on-site counterboring needs.

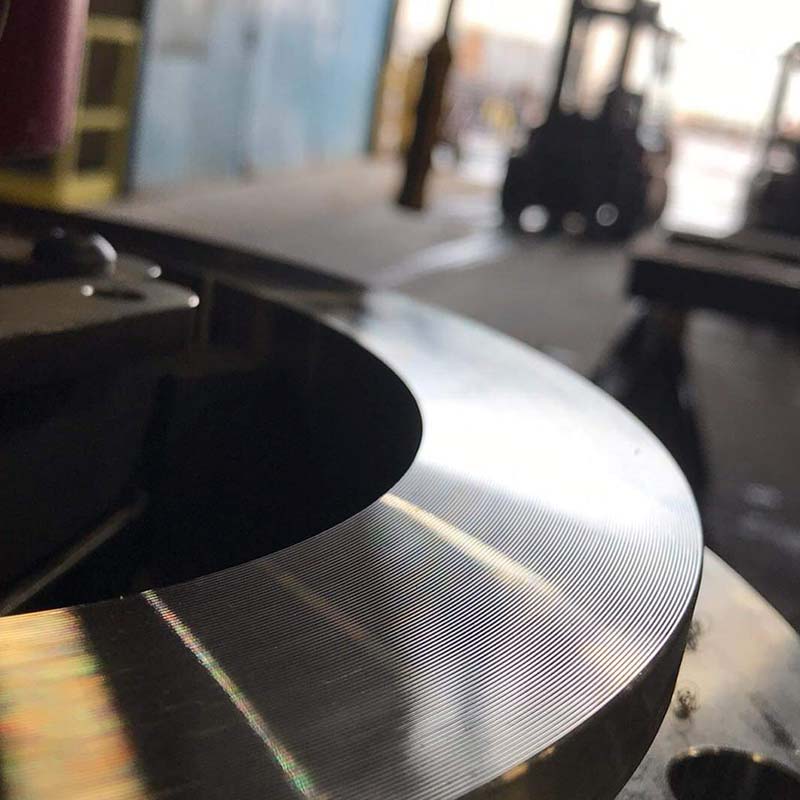

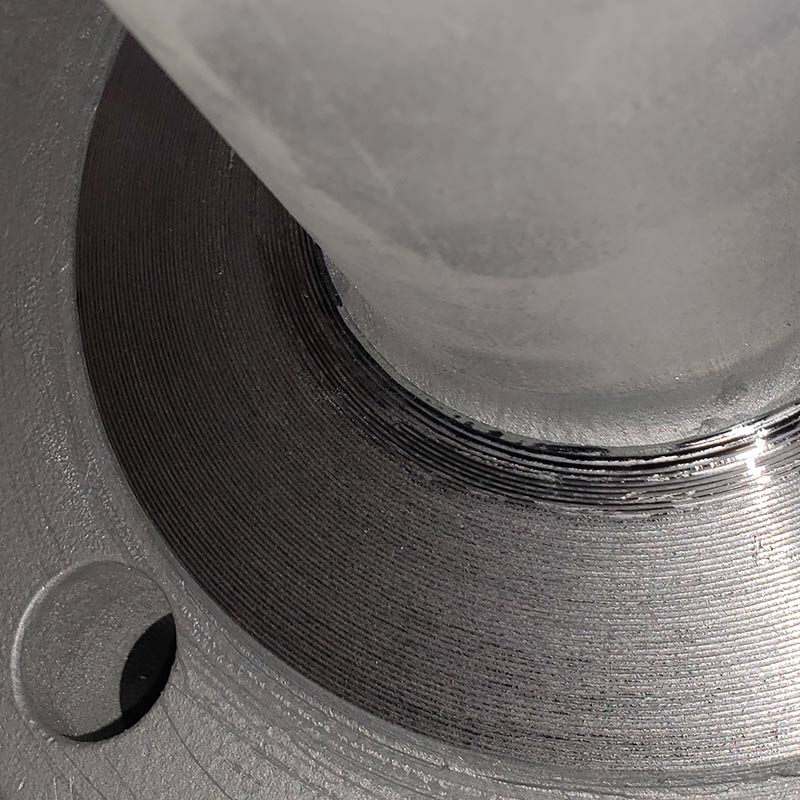

What is Counterboring?

Counterboring is an essential machining process that involves enlarging a pre-existing hole to create a flat-bottomed, cylindrical cavity. This cavity accommodates the head of a screw, bolt, or other fastening devices, allowing them to sit flush or below the surface of the workpiece. Counterboring can be performed using specialized cutting tools, such as counterbore cutters, on a range of materials, including metal, wood, and plastic.

The Importance of Counterboring

Counterboring offers several benefits to industrial operations:

Aesthetic appeal: By recessing fasteners, counterboring enhances the appearance of the final product by creating a smooth, unobtrusive surface.

Load distribution: Counterbored fasteners distribute loads more evenly across a broader surface area, improving the overall strength and stability of the connection.

Enhanced safety: The flush or recessed placement of fasteners reduces the risk of injury from protruding hardware and minimizes snagging or interference with other components.

Easier assembly: Counterbored holes simplify assembly by allowing for the precise alignment of parts and ensuring that fasteners are fully engaged.

Key Applications of Counterboring

Counterboring is widely utilized across various industries for numerous applications, such as:

Manufacturing and assembly: Creating precise, flush connections for parts and components in industries like automotive, aerospace, and heavy machinery.

Construction: Securing structural elements, such as beams and supports, with a strong, visually appealing connection.

Electronics: Recessing fasteners in printed circuit boards and electronic devices to ensure proper functioning and appearance.

Woodworking: Enhancing the aesthetics and stability of furniture, cabinetry, and other wood products.

At Houston Services Field Machining, we understand the critical nature of counterboring for various applications. Our team of experienced professionals is equipped with state-of-the-art machinery and tools to deliver accurate, efficient, and reliable counterboring services. We pride ourselves on our commitment to quality and our ability to tackle even the most challenging projects.

Why Choose HSFM for Your Counterboring Needs?

When you partner with HSFM for your on-site counterboring services, you can expect:

Unparalleled expertise: With over 30 years of experience in the field, our skilled team has honed their craft to deliver exceptional results, every time.

Precision and accuracy: Our advanced equipment and rigorous quality control measures ensure that every counterbored hole meets your exact specifications.

Cost-effective solutions: We understand the importance of minimizing downtime and maximizing productivity. Our efficient processes and competitive pricing ensure that you receive the best value for your investment.

Customization: We tailor our counterboring services to meet the unique needs of each client and project, delivering solutions that align with your specific requirements and objectives.

Comprehensive support: From initial consultation to completion of your project.

With extensive experience, a focus on safety and quality, and competitive pricing, Houston Services is the premier choice for custom on-site machining solutions.

Houston Services Field Machining

Houston Services Field Machining is a reputable provider of top-quality on-site field machining and FCCU slide valve repair services, utilizing cutting-edge equipment and techniques to deliver efficient and cost-effective solutions.